by Johnny Drain

This series is about oxidation, rancidity, and aging butter. Part 1 gave some background about butter, rancidity and the cultural context for eating aged butter. Part 2 explored the science of oxidation in fats and the safety of eating them. In this part I’ll describe the results of my work on culturing butters with unusual sources of bacteria, and on aging butters in Part 4.

Found in the biome of healthy intestines, vaginas and faeces, Lactobacillus brevis might not strike you as the best thing to make butter with. However, as I found out, this pervasive bacteria, which is, reassuringly, also used in beer-making and pickling, can be used in conjunction with Finnish viili to make some top-notch cultured butter.

Cultured butter

Butter churned from fresh cream, irrespective of the quality of the cream, is somewhat bland. To unleash the full flavour potential of butter, the cream used to make it first needs to be cultured, that is, allowed to be fermented by lactic acid bacteria. Lactic acid bacteria, henceforth LAB, are a family of bacteria that are used widely in the making of other dairy products, such as cheeses and yoghurts, and in the pickling of vegetables (sauerkraut, kimchi, nukazuke), baking, wine-making, sake-making, and the curing of fish and meats [1]. Most European butter is cultured, whereas much of the butter sold in the USA is uncultured and is known as sweet cream butter.

LAB produce lactic acid, which makes the cream more acidic (lowers its pH) and can make it taste tangy, tart, and refreshing. Some LAB can also produce a variety of aroma compounds, most notably diacetyl, which can give rise to a richer, more complex, and characteristically ‘buttery’ flavour. Diacetyl also lends richness and butteriness to Burgundy whites and Chardonnays via malolactic fermentation. In beer-making, the presence of diacetyl was seen traditionally as a flaw, but in recent years have been reclaimed by some contemporary brewers as a desirable taste property—a notable precedent for the current project, and how we hope to encourage people to re-examine how oxidised and rancid characteristics might contribute similarly positive properties to butter.

Unpasteurised milk, and therefore cream, naturally contains a variety of LAB strains, alongside many other microbes. LAB are also present in the air, on plants, on our skin, and all around us; traditionally, spontaneous culturing of cream in an open vat was how cultured butter was made. Today, cultured butter, even that made by non-industrialised processes, is often made from cream that has been pasteurised and then had cultures of known bacteria added to it.

Lactic acid bacteria

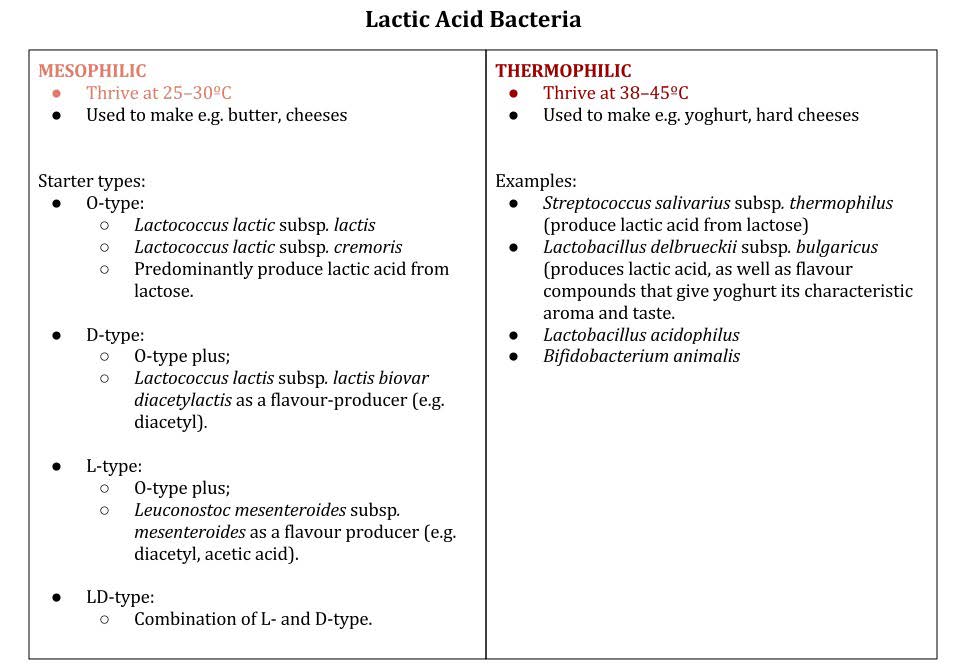

During fermentation, LAB use lactose (milk sugar) to make ATP energy for themselves: a by-product of this process is lactic acid. LAB can be split into two groups: mesophilic LAB, which thrive at ~25–30˚C, and thermophilic LAB, which thrive at higher temperatures, ~38–45˚C. Thermophilic LAB are used typically to make yoghurt, whereas butter is typically made with mesophilic LAB. Some common LAB starter types used in butter-making are given in Figure 1.

Figure 1. Classification of lactic acid bacteria commonly used in culturing butter and yoghurt

The project

As the first step of the project, I wanted to create a flavoursome ‘base’ butter that we could use as the starting point for making the aged butters that I’ll discuss in Part 4.

Having read about chefs at Atera, NYC, making butter cultured with rinds of washed-rind cheeses (Josh tried it made with ‘Arpeggio’), and Patrik, the Butterviking, making butter with cream cultured by having the chefs at Noma dunk their hands in it, I was interested in exploring butters cultured using unconventional sources of LAB.

Viili

A few months before I arrived at the lab, Edith had done a project on Finnish viili, a yoghurt-like substance, often described as “ropey milk”, that is produced by a colony of symbiotic microbes (just like kefir and kombucha).

While variations between different viili cultures almost certainly exist, in general they are said to contain Lactococcus lactis subsp. cremoris, Lactococcus lactis subsp. lactis biovar. diacetylactis, and Leuconostoc mesenteroides subsp. cremoris. It is the latter, which produces exopolysaccharides such as dextran, that is the source of the slimy texture of viili and other similarly ropey fermented foods.

As can be seen from Figure 1, with these three bacteria present, viili is very similar to a mesophilic LD-type starter, but without Lactococcus lactis subsp. lactis. That is, it is very similar to many starter cultures that are used to make cultured butter.

Viili also contains Geotrichum candidum, a fungus found on many bloomy-rind cheeses, most famously Camembert, and which gives viili its characteristic white, velvety surface. Meanwhile, on the surface of fruits and vegetables such as peach, nectarine, tomato, carrot and lemon, Geotrichum candidum can also cause Sour Rot leading to slimy secretions, also from the production of exopolysaccharides. But we’re more interested in the former.

Figure 2. Viili.

Figure 3. Viili surface with Geotrichum candidum

Viili butter

With the addition of a few rounds of fresh milk, I was able to nurse Edith’s viili cultures back to full strength within a week, and used them to inoculate some cream. The butter I made with the viili-cultured cream was buttery, but tasted slightly musty, like old hay: not so good.

Furthermore, after 48 hours, the pH was only ~5.1 and it lacked the characteristic tang of a really good butter: it was clear that we needed to adjust the LAB in order to make the cream more acidic. This was important not just for taste but also for safety: culturing cream to a pH of ~4.2–4.5 ensures that it is inhospitable to pathogenic microbes.

Our approach was to complement the viili by adding lactic acid-producing LAB commonly used in beer-making. We already had samples of these in the lab (because of previous brewing projects) and they were particularly well-suited to our aims because they are commercially available in monocultures and can be stored stably for quite a long time.

The beer-making LAB we used included: Pediococcus damnosus (sours and produces diacetyl); Lactobacillus delbrueckii (produces moderate acidity and sour flavours found in lambics, Berliner Weiss, sour brown ale and gueuze); and Lactobacillus brevis (typically produces more lactic acid than L. delbrueckii). Though L. brevis is found in some cultured butters, it is not one of the most commonly used LAB, despite its ability to produce significant amounts of diacetyl [2].

In combination with the viili, the L. delbrueckii produced great cream and butter, but the L. brevis produced even better results (richer, more buttery). In contrast, the P. damnosus produced cream that had an unpleasant bready, yeasty aroma and did not acidify to a safe level. I also tried culturing cream with only L. brevis (i.e. no viili), but this produced a cream that was bitter, cheesy and tasted slightly of toasted rice: it was the LAB and fungus in the viili in combination with the extra kick of acidity provided by the L. brevis that gave rise to the best possible butter from our tests.

A brief digression on Lactobacillus brevis

Like many bacteria, L. brevis has a multitude of uses:

– It’s found in pickles and kefir

– It’s used in beer-making, but an abundance of it leads to spoilage

– It’s found in the microbiome of healthy oral cavities [3], vaginas [4] and faeces [5] of humans

– Its ingestion has been shown to improve human immune function [6]

– Multiple strains have been patented for use in various novel technologies, often in probiotic systems [7]

Recipes

Figure 4. Lower left: Viili/brevis butter; Upper left: Villi/brevis butter, ‘underchurned’, à la Butterviking’s Virgin Butter; Right: Caraway and cascara butter

Basic butter: viili + L. brevis

500 g pasteurised, unhomogenised cream (Naturmælk’s 38% piskefløde, pH 6.9)

5 ml Lactobacillus brevis culture (White Labs WLP672)

20 g viili starter

1. Mix ingredients in a sterile container. Leave at room temperature for 48 hours. The final pH should be ~4.5, and the temperature of the cream should be stable at ~24˚C throughout.)

2. Churn in a stand mixer with a dough hook until the butterfat and buttermilk separate. Pour off the buttermilk and save.

3. Work the remaining buttermilk out of the butter with a wooden spatula (a process known as ‘throwing’), washing periodically with fresh water.

4. Add salt to taste.

Yield: ~200g butter, ~250g of buttermilk.

The viili/brevis butter is intensely buttery, deeply creamy, tart and a little fudgey.

Caraway and Cascara Butter

Jason’s work on tea and coffee analogues and a chance encounter with Anette Moldvaer from Square Mile Coffee led to us receiving some bags of cascara (thanks Anette!). Cascara are the dried skins of coffee cherries, a by-product of coffee bean production. In addition to brewing tea with them, we noted that their flavour complimented that of caraway, a member of the Apiaceae family (carrot, celery, parsley) that is native to Europe, north Africa and western Asia, and which has long been used as a primary flavouring in Scandinavian Akvavit.

20 g roasted cascara (Los Alpes Cascara, produced by Aida Batlle in El Salvador)

10 g caraway seed

1. Lightly toast the caraway and cascara in a pan. Blitz to a fine crumb in a food processor; mix into the ‘basic’ butter during step 3.

2. Add salt to taste.

Serve on sourdough (esp. if you have access to that of Jonas Astrup Pedersen) or with grilled fish.

Figure 5. Cascara

Figure 6. Cascara tea

Clarified Crab Butter

Curious things often get brought to the lab. During my stay, as part of a project on Round Goby, (a fish invasive to Denmark, for which there are limited culinary uses; the fish are small, bony and not that flavoursome), we received delivery of a crate of Carcinus maenas (aka European green crab or shore crab). Carcinus maenas are also small with little meat to them, and are, as such, unprofitable by-catch for many Danish fisherman. Furthermore, they are invasive to the US and parts of Australia where they have a dramatically negative impact on other species, particularly smaller shore crabs, clams, and small oysters [8].

I made a butter by boiling my cultured cream with the crabs, before churning it. The results were quite fascinating: everyone who tasted it blind said it reminded them of brioche or pastry dough, but with some additional x-factor that they couldn’t quite place.

The boiling of the cream is almost certainly where some of the “pastry dough” notes came from: essentially by boiling the cream we’d caramelised some of the milk sugars in the cream.

500g cultured cream as per basic butter

500-750g of Carcinus maenas (European Green crab)

1. Freeze crabs.

2. Blanch in briskly boiling water for 3 minutes

3. Drain crabs and add to cream: bring to a gentle boil and simmer for 30 minutes. Skim off any scum and skin that forms.

4. Discard crabs and retain cream.

5. Chill the cream to 10ºC. Then churn. Add salt to taste.

Figure 7. Crabs

Figure 8. Crabs ‘n’ cream

A selected history of my many failures:

–Cheese-rind cultured butters made using various Nordic cheeses including the Danish Thise Mejeri Thybo Ost and Hodde Kristian Øko, and the Swedish Jürss Mejeri Granbarksost. These fermentations were difficult to control and produced some very funky, tangy, potent results. I didn’t produce anything I was happy with but I think this approach is worth pursuing further and could produce some truly extraordinary results.

–Cream cultured with bee bread, which typically contains many LAB strains. Some of the creams developed floral and fruity (pineapple) notes but did not thicken or reach a satisfactorily low pH. Perhaps this particular bee bread had lost some of its culturing potency in storage? Definitely worth trying further with some fresh bee bread.

–Inoculated butters: I tried to grow moulds (Aspergillus niger, Penicillium camemberti) and bacteria (L. brevis) on the outer surfaces of butter pats in a process analogous to how bloomy-rind and washed-rind cheeses are made. However, my efforts were not successful, probably because there was insufficient water in the butter matrix (butter typically contains less water than cheese) and/or insufficient protein (butter contains very little protein, in contrast to cheese) to nourish the moulds. However, microbial growth might perhaps be achieved if the surfaces were washed once (or multiple times for Brevibacterium linens, one of the quintessential cultures of washed-rind cheeses) with buttermilk, which contains both water and all the milk proteins that don’t make it into butter—an idea for further experiments.

Figure 9. Mould failing to grow on the surface of butter.

Coming up: With a great-tasting ‘basic’ butter to use as a starting point, I began exploring if we could develop desirable flavour profiles from controlling the aging conditions of butter.

References

[1] European Food Information Council (1999), http://www.eufic.org/article/en/artid/lactic-acid-bacteria/

[2] Christensen, MD., & Pederson, CS. (1958). Factors affecting diacetyl production by lactic acid bacteria. Applied Microbiology, 6(5), 319–322.

[3] Walter, J. (2008). Ecological role of Lactobacilli in the gastrointestinal tract: implications for fundamental and biomedical research. Appl. Environ. Microbiol. 74(16), 4985–4996.

[4] Vásquez, A., et al. (2002). Vaginal Lactobacillus flora of healthy Swedish women. Journal of Clinical Microbiology. 40(8), 2746–2749.

[5] Wilson, M. (2005). Microbial inhabitants of humans: Their ecology and role in health and disease. Cambridge University Press. 398.

[6] Kishi, A. et al. (1996). Effect of the oral administration of Lactobacillus brevis subsp. coagulans on interferon-alpha producing capacity in humans. Journal of the American College of Nutrition. 15(4), 408–412

[7] Castellana, JP. (2015). Probiotic composition for oral health. USPTO Applicaton #20150273000 A1. (Also, see http://tgs.freshpatents.com/Lactobacillus-bx1.php)

[8] Washington Department of Fish and Wildlife Conservation, http://wdfw.wa.gov/ais/carcinus_maenas/