Researcher: Alec Borsook

Start: June 2014

End: August 2014; ongoing

Overview

Alkali cooking techniques are largely underexplored in contemporary kitchens. This post is a basic overview of what alkalis are, what they do, and how they can be useful.

A notable fact is that calcium hydroxide (Ca(OH)2), one common alkali, can be made quite easily in kitchens by burning eggshells, whose calcium carbonate is then converted into calcium oxide (quicklime, CaO), which can be ‘slaked’ with water to become calcium hydroxide.

Acidity comes in many delicious forms. Much of the research performed here at the Lab concerns our unending search for them, from our exploration of sour wild things to our investigations of the possibilities of lactic and acetic acid fermentations. Acids can balance flavours, providing brightness and cutting through richness, or they can make you pucker your lips in a delight bordering on pain. But what about their chemical opposites, the alkalis?

In continuation of some previous forays into the subject, last summer we conducted a survey of alkaline cooking methods. Baking soda, or sodium bicarbonate (NAHCO3), is probably the most frequently found alkali in the kitchen, used in conjunction with an acid as a leavening agent. Other alkalis, such as quicklime (CaO, calcium oxide) and potash (encompassing various salts of potassium), are generally less frequently encountered, and not without reason: they can taste bitter and soapy and even inflict chemical burns on the incautious. But when used deliberately and with care, alkalis comprise a versatile culinary toolkit, capable of altering the flavour, texture, and appearance of foods to delicious effect.

The basics – what is an alkali?

In any aqueous solution, water (H2O) exists in equilibrium with its ionized forms, the protonated hydronium ion (H3O+, often written as simply as a proton, H+) and the deprotonated hydroxide ion (OH–). Acids are those substances that shift this equilibrium toward the hydronium ion. Alkalis, or bases, favour the hydroxide ion.

The pH of a solution is a measure of its acidity or alkalinity, calculated as the negative logarithm of the hydronium ion concentration. The pH scale is centered at 7, at which hydronium and hydroxide ions are present in equal concentrations. Lower pH values correspond with acidity and greater hydronium concentrations, higher pH values with alkalinity and greater hydroxide concentrations. Common food molecules like proteins, carbohydrates, and fats may exhibit different properties in different environments, and adjusting the pH of a food is one way to significantly alter its sensory qualities.

Alkalinity and proteins

Proteins consist of long chains of amino acids, or polypeptides, folded into a specific three-dimensional shape. This shape is determined largely by the amino acids’ interactions with each other, the aqueous solution surrounding them, and by the action of enzymes that modify the folding process following synthesis. A protein tends to fold into a conformation that minimizes the energy of the system – that is, the protein and its environment. For example, positive charges move as far away from each other as possible, and the bonds between positively and negatively charged chemical groups are maximised.

Lowering the pH of a food by, say, marinating it in vinegar, involves surrounding its proteins with hydronium ions, which can donate positively charged protons to parts of amino acids along the chain, among other effects. Chemical groups in the protein and the surrounding solution rearrange themselves accordingly, and the protein changes shape – it becomes denatured. This process can alter the texture and appearance of foods, as occurs in seafood ‘cooked’ in acid in a ceviche.

Proteins can just as easily be denatured by adjusting the pH in the opposite direction – by marinating food in an alkaline solution instead of an acidic one. Whereas acids donate protons to various chemical groups within proteins, alkalis tend to pull them away, which can have a different but comparable effect on protein structure.

Alkaline brines and marinades are frequently employed in Chinese cuisine to alter the texture of meat or seafood. Before cooking, shrimp are soaked in a mixture containing a weak alkali, such as sodium bicarbonate, or egg whites, which are naturally alkaline. Shrimp prepared in this manner develop a firm, almost crunchy texture, yielding between the teeth with a satisfying pop. A similar marinade containing baking soda or egg whites can be applied to slices of meat in a technique called ‘velveting’, yielding a downy soft cooked product (Wang, 2011). To know what effect alkaline treatment might have on a specific protein seems to require a bit of experimenting: our sodium bicarbonate-treated shrimp were firm and delicious, but we found no such success in applying this treatment to scallops, which grew soft and developed a faint odor of ammonia when cooked.

Our trial involved three brines and two soaking periods:

Brine 1 (control): 40 g salt in 1 L water; pH ~6.5.

Brine 2: 40 g salt, 40 g sodium bicarbonate in 1 L water; pH ~8.0;

Brine 3: 40 g salt, 2 drops 33% potassium carbonate in 1 L water; pH ~9.4

Each brine was used to marinate shrimp for 1.5 hours or 15 minutes. The shrimp were then sautéed in butter and served. In direct comparisons, there was a noticeable difference in texture between the alkali and non-alkali brined shrimp, with the alkali brine imparting a ‘bounce’ or almost crunch to the flesh of the shrimp.

Stronger alkaline treatments can increase the chance of breaking down fats and developing soapy flavours, but they are applied to great effect in developing the characteristic flavours and textures of delicacies like the Nordic lutefisk and the Chinese pidan, or century egg.

Alkalinity and Maillard reactions – interactions between carbohydrates and amino acids

Alkalis can also be used to increase the rate of Maillard reactions, the group of chemical reactions between amino acids and sugars responsible for the deep brown colour and complex flavour of many of our favourite foods. Perceptible Maillard flavours may emerge in seconds, as in a seared piece of meat, or more slowly when temperatures are lower – over a period of weeks in the case of black garlic.

Alkaline conditions facilitate Maillard reactions because they pull protons away from the nitrogen-containing amine groups in amino acids, making them more likely to react with sugars. The distinctive flavour and deep brown colour of pretzels, for example, is achieved by a dip in an alkaline solution before baking in a hot oven.

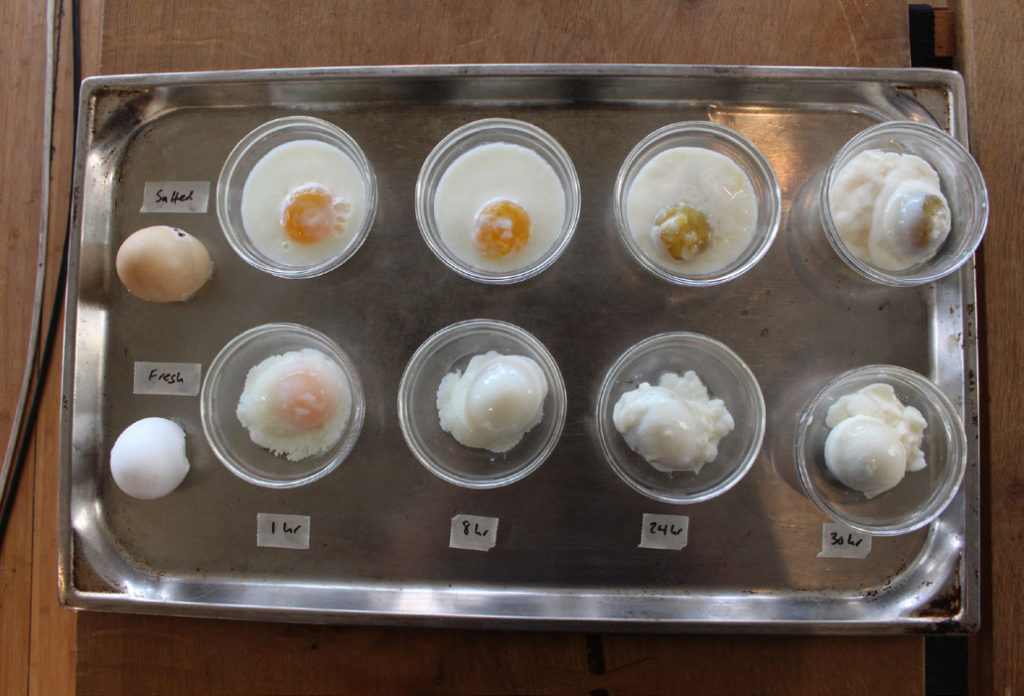

A traditional preparation in Sephardic Jewish communities calls for eggs to be simmered overnight, by the morning yielding egg whites with a light brown tint and some of the nutty, meaty qualities generated by Maillard reactions. Although the temperature of these ‘Sephardic eggs’ or huevos haminados never exceeds 100ºC, an impressive reaction can be produced within hours due to the natural alkalinity of the egg white, promoting reactions between the amino acids and sugars in the white. By this method, a complexly flavoured egg can be produced while retaining some of the desirable qualities provided by lower cooking temperatures – Harold McGee specifies a range between 71 and 74ºC (McGee 89).

We attempted preparing Sephardic eggs at a lower temperature, 66ºC, but even after 24 hours, this temperature resulted in a barely visible reaction and imperceptible Maillard flavour. A couple of weeks later, however, an event left us with a silly number of extra eggs, and we tried again – this time the process worked. As eggs are stored, carbon dioxide, which is weakly acidic, diffuses out of the egg, and the pH of the white steadily increases from about 8.5 at one day old to as high as 9.4 at ten days (Scott and Silversides, 2001). An egg a couple of weeks after being lain, then, should be primed for browning. 24 hours at 66ºC produced a custardy, sandy-coloured egg, buttery and mineral and already beginning to taste like chicken.

These trials with eggs have prompted us to consider other foods that might benefit from slow cooking under alkaline conditions. While naturally alkaline foods are somewhat unusual, adjusting the pH of foods with an alkaline brine before cooking may prepare them to quickly undergo Maillard reactions even at relatively low temperatures, creating possibilities for new combinations of flavour and texture.

pH and colour change

pH can affect the colour of food much more than just the range of Maillard browns. The colour of many anthocyanins – compounds that give foods like red cabbage and blueberries their brilliant colours – changes with pH, such that red cabbage juice can be used as a pH indicator. A drop of anthocyanin-rich cabbage juice will appear red in a low pH solution, blue in a higher pH one, and eventually green and yellow in even more alkaline solutions. Another example of naturally occurring, pH-sensitive pigments can be found in litmus, a dye extracted from lichen that follows a similar progression from red at low pH to blue at high pH.

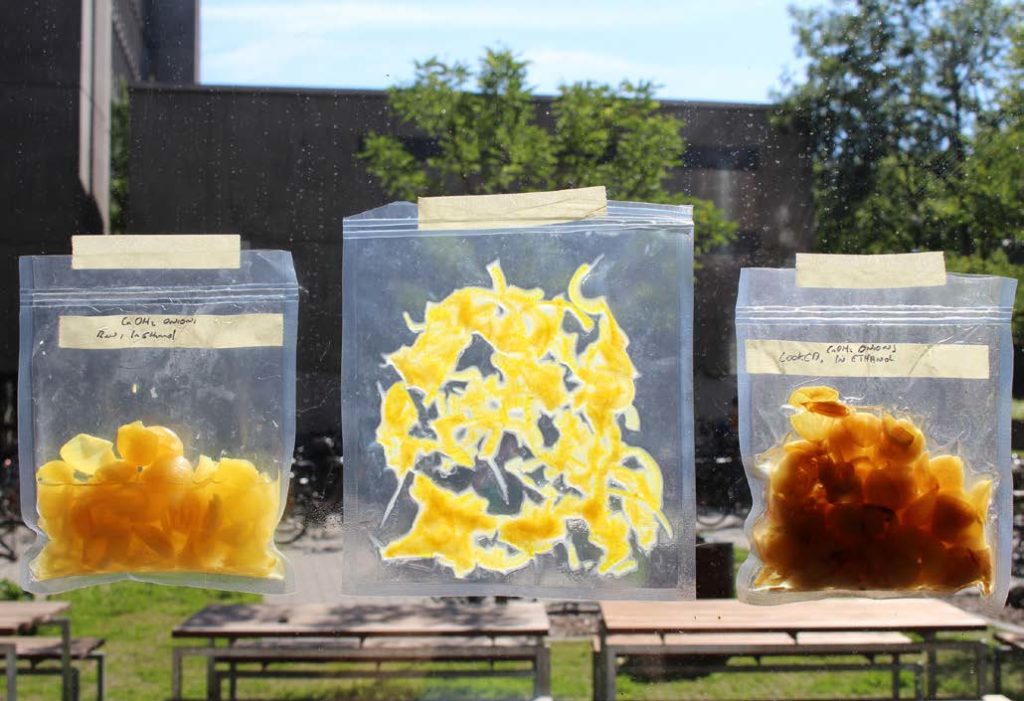

More recently, this summer we observed that onions soaked in an alkali solution turn bright yellow and developed a distinctive aroma, very much like corn chips. Originally we thought this might be due to polymerisation of sulphurous compounds in alliums facilitated by the physical and chemical breakdown of the allium tissues due to exposure to the alkaline solution, though subsequent trials point towards other compounds – perhaps quercitin, an antioxidant flavonol responsible for over 85% of onion’s flavour and with yellow pigmentation which becomes enhanced when it polymerises. Thanks to Karsten Olsen at the Department of Food Science at Copenhagen University for helping us track down this specific mechanism – we look forward to publishing more information on this process and its culinary potential in a future post.

Sources of alkalinity

Alkalis, like acids, are highly variable in both strength and their suitable applications in the kitchen. Baking soda is a pantry staple, a mild alkali and convenient chemical leavening agent due to the carbon dioxide released by the bicarbonate ion’s reaction with acid. However, it is too weak of an alkali for certain applications.

Potassium carbonate (K2CO3), quicklime/calcium oxide (CaO), and sodium hydroxide (NaOH) are all stronger alkalis that can be purchased as solids or in solution for food use, but they are not necessarily easy to find or convenient to keep on hand, being highly caustic and easily mistakable for, say, salt. Following traditional methods, it’s a relatively simple matter to prepare alkaline solutions of comparable strength as needed, often using materials that might otherwise be thrown away.

The shells of eggs and bivalves like mussels or oysters are composed largely of calcium carbonate (CaCO3), a weak alkali. Calcium carbonate is not highly soluble in water, but the shells, heated briefly in a flame to burn away the residual membrane and its eggy odour, can be crushed and mixed with water to produce a solution of around pH 8.5, similar to what we can make with baking soda. When the shells are heated very strongly, until they turn black, ideally red hot, then white or grey, their calcium carbonate is converted to quicklime, or calcium oxide (CaO), which forms calcium hydroxide (Ca(OH)2) when ‘slaked’ or mixed with water. Applying this procedure to eggshells, we produced a highly alkaline solution of pH 12.2. Quicklime is suitable for nixtamalising grains for tortillas and tamales, being a relatively strong alkali and containing the calcium necessary to form a cohesive masa (a topic on which Dave Arnold has produced an excellent resource, and on which we will be sharing some of our own results soon).

Wood ash also consists largely of calcium carbonate, with smaller quantities of potassium salts and other minerals. We punched some small holes in a container, lined the bottom with small stones, and filled the container with sifted ash from our grill. By repeatedly filtering water through the ash, we obtained a transparent, yellow-tinted solution of pH 12.6, which, for our purposes, is as strong as we need.

A note on safety

Despite their interesting applications, it’s important to be aware that alkalis are hazardous chemicals, and certain safety precautions should be observed in their use. Strong alkalis in solid form or in solutions with a pH of around 10.5 or higher are caustic and can corrode skin and other tissues. When handling these strong alkalis, gloves and goggles should be worn. If a strong basic solution splashes on a person’s skin or eyes, the exposed area should be flushed with cool water for several minutes. Spills should be neutralized with vinegar or another acid before being cleaned up.

Unlike some other classes of chemicals, however, alkalis are non-toxic at low concentrations and don’t pose a risk of accumulating in the body, so alkalised foodstuffs carefully prepared are safe to eat. Where strong alkaline treatments are applied, rinsing and/or soaking alkalised foods in water seems to be the general practice preceding any final steps in preparation – nixtamal is rinsed after the alkaline boil and soak and before being ground into masa, for example, and lutefisk is soaked in several changes of water before cooking.

More

We have been conducting more research on several specific applications of alkalisation, so stay tuned as we delve into some extensions of this fundamental aspect of cooking.

References

Block, Eric. Garlic and Other Alliums: The Lore and The Science. Royal Society of Chemistry, 2010.

McGee, Harold. On Food and Cooking. New York: Scribner, 2004.

Silversides, F.G., and T.A. Scott. 2001. Effect of storage and layer age on quality of eggs from two lines of hens. Poultry Science 80 (8): 1240-5.

Wang, Chichi. “Seriously Asian: Velveting Meat.” Serious Eats, 1 April 2011.