by Ben Reade.

Love for the umami tasting compounds that yeast extract can give led NFL to investigate the process of making yeast extracts; the secrets of which are closely guarded by the flavour industry. Our aim was to produce a delicious yeast extract that could be useful in food production. Yeast is a an underutilized waste product of the brewing industry (Ferreira, 2010), however, if waste yeast is taken from the bioethanol industry it may not need to be debittered as it contains no bitter chemicals (especially humulene) from the hops used to make beer.

Other uses for waste yeast include the manufacture of Single Cell Proteins (SCP), a term coined in the 1960s to define microbial biomass from fermentations. SCP have been shown to be promising in filling a global protein deficit although currently most waste yeast is used as animal feed (Ugalde and Castrillo 1992). During the Second World War most protein consumed in Germany was from yeast, and the English yeast extract, ‘Marmite’ was invented during the same challenging times to assist public health in Britain (Ugalde and Castrillo 1992).

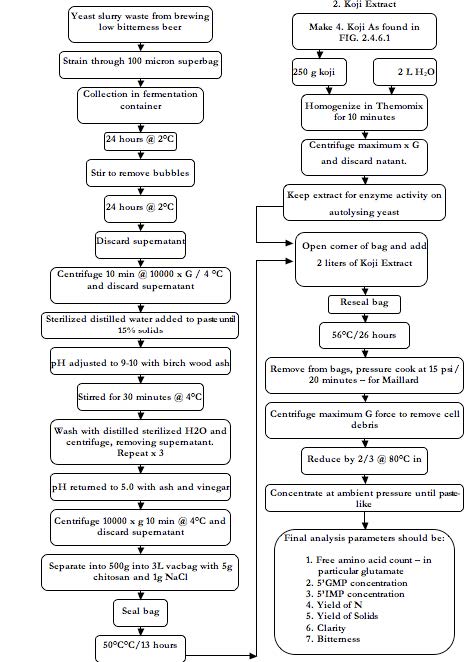

Yeast extract production is normally carried out through the process of autolysis triggered by salt. Autolysis is the process by which a cell will consume itself using enzymes contained within the same cell. Origane et al (1993) found that addition of the fat binding chitosan (extractd from prawn shells) improved autolysis. We found that this helped not only autolysis but also caused a reduction in bitterness – presumable because many bitter compounds are capable of a type of chemical binding compatible with chitosan. Autolysis involves a freeing of enzymes within the yeasts in order to break down the yeast proteins. The protein should be hydrolysed as far as possible into individual amino acids to increase content of umami tasting compounds however, amino acids are also sweet and bitter, or a mixture, so the type of yeast used can have a large effect on the final product. To help with lysis the extract can be performed using extrogenous hydrolyzing enzymes (Sombutyanuchit et al 2001). Hyoky (1997) also found the breakdown of yeasts using extrogenous enzymes to be fruitful- we have used this technique in the creation of in the recipe supplied in this post, where we use koji as a source of hydrolyzing enzymes. However, if you don’t want to make koji, autolysis with endogenous enzymes is normally adequate for processing (Cahyanto et al, 2011).

Boonyeun (2011) found that amino acid content can be enhanced by a two stage autolysis. The first stage encourages breakdown through high enzyme protein concentration, the second, by dilution with water causes a higher concentration gradient leading to higher extraction from yeast cells. Yeast extracts may also contain 5’-GMP, a compound often found in mushrooms, which is synergistic with glutamate, increasing umami taste.

Ideal temperatures for autolysis depend on exact strains and desired results. Tangluer and Erten (2008) found that 50°C for 24 hours was ideal for autolysis. We found that a period at 50°C and a period at the raised temperature of 56°C to encourage optimize enzymatic action raised the acceptability of the extract – however, each type of yeast should be investigated individually.

To sterilize and encourage flavour enhancing Maillard reactions, the extract can be treated in a pressure cooker at 115°C for 20 mins before being reduced in volume through evaporation (Ke-de, 2006). Polymeric absorbents (especially Amberlite XAD-16 and Amberlite XAD-765) have been used to remove bitterness and yeast flavour from yeast extracts while keeping desirable components including yeast peptides, amino acids and neucleotides (Hyoky, 1997; Kerler and Winkel, 2002).

Cahyanto et al (2011) found that optimum pH of autolysis was at pH5. In commercial processing pH is adjusted with NaOH and HCl. Both of these chemicals leave traces in the final product, which, due to a desire of NFL to use natural products, was not considered optimal. Raising pH to strongly alkali is also used industrially in the debittering process. Instead of adjusting pH using Alkali NaOH, we used birch ash, rich in K2CO3 (a salt which forms a strongly alkali solution) The ash is also considered by many as having health promoting qualities. For acidifying the mixture afterwards, a strong vinegar was used and results were very delicious.

So, how does one actually make it, the recipe below tells you how to make it with a centrifuge (no, not a juicer, but one of the things used in hospitals for separating blood by spinning it super fast), however, we started this investigation before we had a centrifuge, and carried out most of the separation with coffee filters, a lengthy, but successful method. The recipe below also calls for the use of a koji extract. This was used in creating particularly delicious yeast extracts, but, as mentioned above, the enzymes within the yeast cells, should be enough for a fairly thorough breakdown if you want to make it without the koji extract then you should add water in the place of the extract.

Bibliography

Boonyeun, P. et al (2011) Enhancement of amino acid production by two step autolysis of spent brewer’s yeast, Chemical Engineering Communications 198 : 1594.

Cahyanto, M.N. et al. (2011) Production of yeast extract from ethanol fermentation waste, The 12th ASEAN Food Conference, 16 -18 June, 2011 Bangkok

Ferreira, I. M. P. L. V. O. et al (2010) Brewer’s Saccharomyces yeast biomass: characteristics and potential applications, Trends in Food Science & Technology 21 : 77.

Hyoky et al (1997) Non-bitter yeast extract, Trends in Food Science & Technology 8 : 383.

Kerler, J. and Winkel, C. (2002) The basic chemistry and process conditions underpinning reaction flavour production’, in Taylor, A.J (ed), Food FlavourTechnology, pp. 27-52, CRC Press, Sheffield, UK.

Origane, A. and Sato, T. (1993) Process for producing yeast extract, USA, Patent No 5188852.

Sombutyanuchit, P. et al (2001) Preperation of 5’-GMP-rich yeast extracts from spent brewer’s yeast, World Journal of Microbiology and Biotechnology 17 : 163.

Tanguler, H. and Erten, H. (2008) Utilization of spent brewer’s yeast for yeast extract production by autolysis: The effect of temperature, Food and BioproductsProcessing 86 : 317.

Ugalde, U.P. and Castrillo J.I. (2002) Single cell protiens from Fungi and Yeasts, Applied Mycology and Biotechnology, 2 : 123.

About the author

My Name is Ben Reade, I’m a chef from Edinburgh, Scotland, and for the past 3.5 years I have been studying at The University of Gastronomic Sciences in Pollenzo, Italy. For my final thesis, I came to Nordic Food Lab to research many subjects where my varied interests inerlaced with those of the Lab. The research arose out of time spent at the Nordic Food Lab between 29 September and 22 December 2011. The aim is to describe NFL’s current research to both chefs and non-specialized readers, explaining and coding the creative and scientific methodologies employed during the research at NFL, exploring their application in food experimentation and innovation. Over the next month or so I will be breaking down this thesis into manageable blog-style chunks, this is chunk 6ish of around 25 I hope you find it interesting.