by Arielle Johnson

Overview

Alcoholic liquids are usually created by allowing yeast to ferment a sugar-rich solution (juice, syrup, etc.). By using distilled spirits, however, we are able to create dilute alcoholic solutions (usually between 5 and 9 percent ethanol by volume) using ingredients that are not usually rich enough in sugar to ferment into an alcoholic product. This post, part two of a five-part miniseries on vinegar science, details how this idea can be combined with a few simple pieces of readily available equipment that enable us to speed up the rate of aeration of the fermenting vinegar, to create interesting vinegars out of wines, juices, and teas much more quickly than traditional methods.

As part of our investigation into new and delicious vinegars, we wanted to experiment with fresh and seasonal summer ingredients, but didn’t want to wait too long to evaluate the results. An aquarium bubbler with an airstone, we discovered, could make a batch of vinegar in around 3-6 days. We used six 1.5 L/min pumps to run six experiments simultaneously. It is also possible to use a manifold, which divides the airflow into several parallel paths, to run several airstones off of one pump (economizing on equipment), but bear in mind that the pressure feeding to each stone will be reduced, which will slow down the fermentation.

[ADDED BY BEN: It is also worth bearing in mind that an airstone producing smaller bubbles will dissolve more oxygen, and the deeper the container, the more liquid the bubbles must rise through, which also dissolves more oxygen – and the more dissolved oxygen available to the acetic acid bacteria, the faster the process.]

Acetic Bacteria and Acidic Liquid

For each batch of vinegar we added 20% by volume of a finished vinegar (either vinegar that we had made, or unpasteurized commercial vinegar), to provide a dose of acetic bacteria and an acidified environment for these bacteria to grow in. When possible we add a vinegar with a complementary flavour – for example a previously-made celery vinegar to a new celery vinegar. When this is not possible, we use a high-quality apple vinegar which is our go-to on the boat.

Alcohol and Flavour Sources

We wanted to cast a wide net when testing primary ingredients and flavours, so we investigated applying vinegar fermentation to yeast-fermented liquids, juices with alcohol added, and other ingredients that are highly flavoured but not juicy. In theory, the alcohol in vinegar fermentation can come from any source, so we have experimented with adding alcohol straight to liquids that don’t contain enough of their own sugar to be fermented by yeast, which we then ferment with acetic bacteria. Based on our experience, a starting alcohol content of 5-9% tends to work well to make a fairly versatile vinegar, best-suited to flavouring rather than, say, pickling purposes.

Wines

We also experimented with using a more traditional fermentation process on sweet ingredients. We made wines out of beets, strawberries, and elderflowers, drawing on some background information from Boulton et al’s Principles and Practices of Winemaking and Jonathan Musther’s excellent website Vinocalc to calculate how much sugar we would need to start in order to reach 5-9% ethanol at the end of the fermentation. 13 degrees brix (13% sugar by weight) will give us about 7% ethanol if we ferment it to dryness (i.e. little to no residual sugar) which is right in the middle of this range, and therefore what we aimed for. With the elderflowers, this meant infusing them into a 13% sugar syrup (lightly acidified with citric acid to lower the initial pH and stabilise the fermentation) to make a dry elderflower wine. Neither strawberry nor beet juice had this level of sugar – both were around 8˚ brix – so we split the juice for each and cooked down half to about 1/4 of its original volume, then recombined it with the remaining fresh juice to get a sweeter product that preserved the fresh aroma of the produce. Then, we gave each a dose of champagne yeast and sealed them in containers with an airlock, to ferment until dry.

While the elderflower and the strawberry wines fermented successfully, the beet wine had a bloom of surface mold or yeast called mycoderma, or ‘flowers of wine’, which had the unfortunate effect of producing quite a bit of ethyl acetate, like the aroma of nail polish. Although we were able to scrape the bloom off and transfer the wine to a new, sanitized container, it soon returned and we were forced to abandon the attempt. Perhaps we had an acidity issue – not enough acid/too high a pH can lead to all kinds of unwanted microbial growth problems, and while we tried to compensate for the natural alkalinity of beet juice by adding tartaric acid [i], this may not have been precaution enough. Or maybe we were just unlucky in this instance. In any case, watch out for that beet wine if you try to make it.

[ADDED BY JOSH: One of our readers recently sent us a comment in which she describes a method of achieving beet flavour in fermented liquids without getting mycoderma. She used whole peeled beetroots to infuse into a simple kombucha base, yielding a fizzy pink drink with prominent beet flavour. This technique could also presumably be used to make beet vinegar without a mycoderma interrupting the fermentation, perhaps infusing into a neutral unfermented vinegar base (such as 73% water, 20% live apple vinegar, and 7% ethanol) prior to active aeration.]

Juices

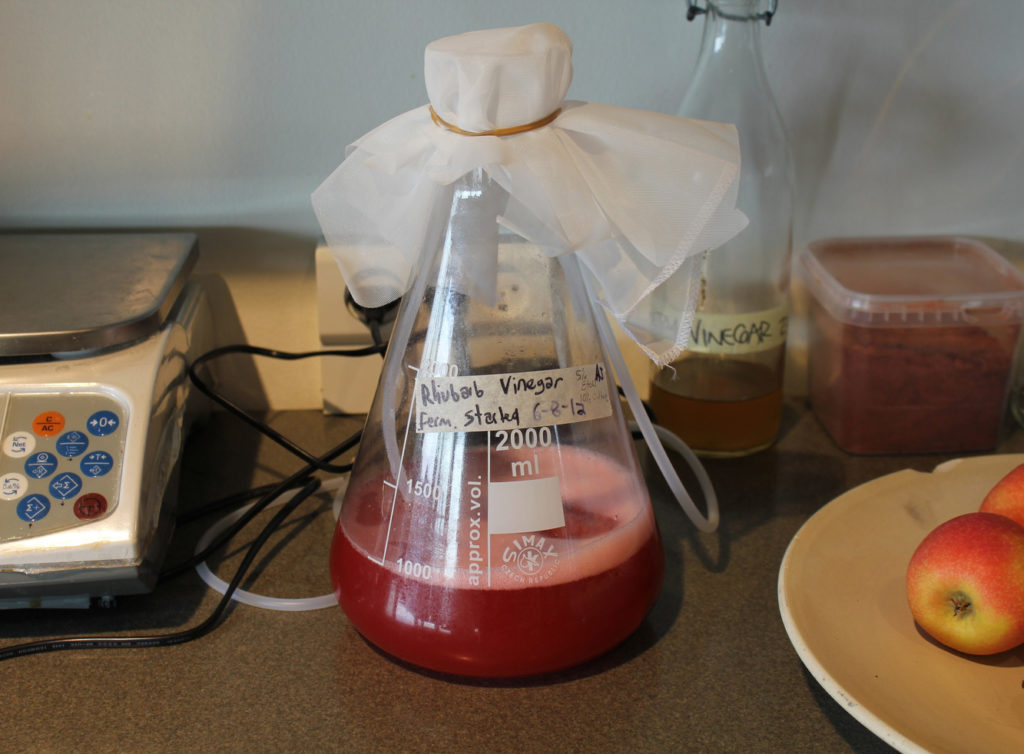

Some of the flavours we hoped to capture in vinegar come from plants that don’t produce much sugar. Rather than making wine we used the rapid-prototyping technique described above, juicing produce and adding high-proof grain alcohol to reach a level of 6-7% ethanol overall. We juiced celery, rhubarb, white asparagus and green asparagus that we left to ferment in the previously mentioned aquarium-bubbler system.

Teas

Other flavours and aromas from the Nordic region we are particularly interested in do not lend themselves to easy juicing in their natural form. Liquorice, in candy form, is extremely popular in Denmark, but the dry and woody texture of whole liquorice roots make them difficult to work with. Pine needles have an intense and complex scent, but mature needles present textural challenges. In both cases, and for a lot of other strongly-flavoured herbs, juicing and adding alcohol isn’t an option for capturing flavour in vinegar as they have very little water content. So instead we made very gently-cooked ‘teas’ by blending these ingredients (pine needles, liquorice roots) to a paste/powder in a Thermomix and heating this with water at 60°C for two hours, giving us an intense but not over-extracted or bitter-tasting infusion.[ii] Once the teas were finished, we treated them like pressed juices, adding ethanol and vinegar starter and aerating.

Next up: once we have vinegars, we can do a sensory analysis of their flavours.

[i] Tartaric acid is the main acid in grapes. It is an organic acid like citric, malic, ascorbic, or lactic acid. Interestingly, while malic and citric acid can be converted by some types of lactic bacteria into lactic acid with some buttery-smelling side products, tartaric acid cannot, and this non-bioavailability to bacteria means it is microbially stable. So, in the interest of reducing interference from side reactions, I used tartaric rather than citric or malic to acidify the beet juice.

[ii] Liquorice root will break down in the Thermomix but is pretty hard on the blade. So expect to get more of a coarse, splintery sawdust than a fine powder.