by Ben Reade.

Chiang is the Chinese prototype of the Japanese miso, and chiang yu is, directly translated, the ‘oil of miso’ otherwise known as soy sauce. Variations of which are a staple condiment for much of Asia, has an ancient history, the first written reports of precursors occurring during the 2nd Century (Huang, 2000). The first prototypes for the modern soy fermentations were carried out using meat and fish as fermentation substrates. The sauces would have been very dark with small particles of enzyme-digested meat in salt solution, and a high level of umami taste. These chiang yu prototypes would have been very varied and it is said that Confucious would not eat a food without its proper fermented sauce (Huang, 2000).

The history of soy sauce most probably starts with solid soy bean fermentations which were subsequently diluted with vinegar (Huang, 2000). Now the common practice is to ferment the sauce with brine, to extract amino acids from proteinous soybeans. At NFL investigation was carried out into the possibility of the creation and use of Nordic adaptations of both soy sauce and its close relative, miso.

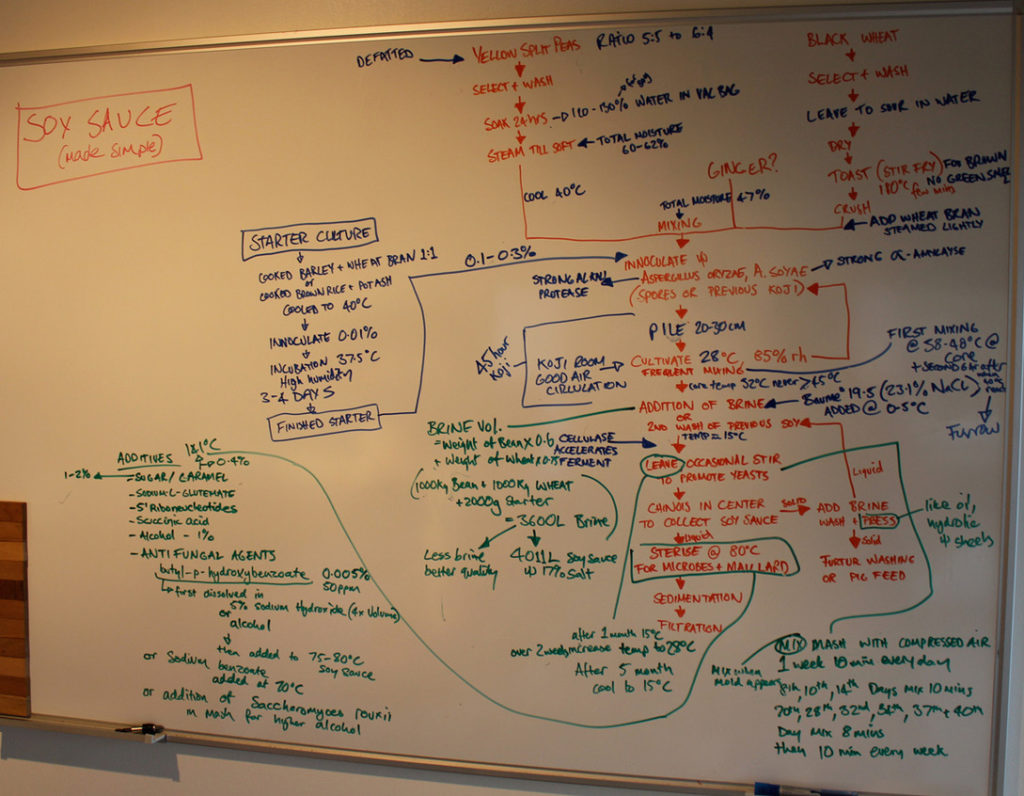

The following (and preceding) photo of a white board covered in my scribblings, explainings the process of Chiang and Chiang yu, as it is made at NFL. the recipe uses yellow split peas (Pisum sativum) due to its high glutamic acid content and presence in traditional Nordic cuisine; and a heritage variety of black wheat, which is being grown experimentally in Denmark on a small organic farm (by the parents of NLF’s boat dwelling neighbour – keeping it local).

The preparation of Chiang yu normally occurs in 7 ‘macro’ stages.

(i) Preparation of the soybeans, in commercial use, defatted beans are used allowing lipid parts to be processed into other products.

(ii) Preparation of starchy substrate, which normally is wheat or barley, although at NFL experimental use of buckwheat (Fagopyrum esculentum) a pseudo-cereal with a long history in the Nordic regions proved successful.

(iii) Preparation of the starter mold culture – usually consisting of Aspergillus oryzae and A.soyae although variations include Monascus strains. More information on molds in soy sauce can be found in a later post.

(iv) Preparation of the koji, a mix of the above (i), (ii) and (iii) which are molded over a few days to create an enzyme rich, fermentable and sweet substrate.

(v) Moromi fermentation is the longest stage in which yeast fermentation (particularly Zygosaccharomyces rouxii) lactic acid bacteria fermentation (usually many wild strains) and enzymatic breakdown of the substrate occurs in salt rich solution.

(vi) The separation of moromi into solid and liquid parts occurs at the end of the process, allowing collection of soy sauce and solid parts. The solid parts can be washed with brineto produce a second grade sauce or may be used like miso paste.

(vii) The liquid should then be processed appropriately, as detailed below, to make a delicious and microbiologically (especially fungi) stable product

Detailed information on the production of fermented soy bean products can be found in numerous books and papers, especially useful are those of Stienkraus, (2004) and Keshun (2004).

Further experimentation is proposed to further develop the recipe given below. Examples of areas of possible experimentation are the addition of spices (such as anise or liquorice), which may improve the sensory properties of the product. Other areas of investigation are experimentation with fermentation vessels, mixing technologies and hydraulic pressing of solid parts to maximize liquid extraction.

Use of various grains and pulses should be further investigated to maximize sweetness and umami taste, as well as general flavour and aroma. As this rich sauce has high gastronomic appeal (many people have tasted it informally at NFL and Noma has now started making 200 kg batches), it is thought by the author that a schematic version of the recipe, as given below (if you can decode my scribbling) is useful to industrial application of the techniques involved in soy sauce which, especially if applied to novel ingredients can be used to create new foods with high marketability.

And today’s Bibliography,

– which, is amazing, but bloody expensive!

Huang, H.T. (2000) Biology and biotechnology, in Needham, J. (ed) Science and Civilisation in China: Volume 6, Biology and Biological Technology, Part 5, Fermentations and Food Science, p. 245, Cambridge University Press, Cambridge, UK.

Stienkrauss K. (2004) http://books.google.dk/books?id=hT1a1xR3n8EC&printsec=frontcover&dq=Keshun+2004+fermentation&hl=en&sa=X&ei=OJlrT7GDOfTP4QTG18SUBg&ved=0CFAQ6AEwBg#v=onepage&q&f=false

Liu, Keshun (2004) Fermented Soy Foods: An Overview, Pages 481-493 in Y.H. Hui and Friberg, Stig (eds) in Hui Y.H. et al. (eds), Handbook of Food and Beverage Fermentation Technology, pp. 552-568, CRC Press.

About the author

My Name is Ben Reade, I’m a chef from Edinburgh, Scotland, and for the past 3.5 years I have been studying at The University of Gastronomic Sciences in Pollenzo, Italy. For my final thesis, I came to Nordic Food Lab to research many subjects where my varied interests inerlaced with those of the Lab. The research arose out of time spent at the Nordic Food Lab between 29 September and 22 December 2011. The aim is to describe NFL’s current research to both chefs and non-specialized readers, explaining and coding the creative and scientific methodologies employed during the research at NFL, exploring their application in food experimentation and innovation. Over the next month or so I will be breaking down this thesis into manageable blog-style chunks, this is chunk 6ish of around 25 I hope you find it interesting.