by Ben Reade.

The Orleans Method

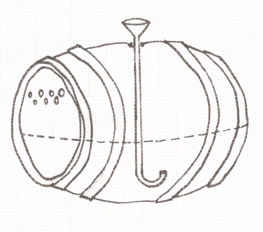

The most famous slow method of vinegar production is the old French technique, known as the Orleans method. In the Orleans method barrels are filled with wine and vinegar and fermentation is carried out slowly by the AAB, which will generally metabolise all the alcohol in a 9 % ethanol wine in 1 to 3 months. When fully acidified, the vinegar is racked off leaving around 12 L inside a 225 L barrel, which can then be filled up to around half full with fresh alcoholic ‘wine’. To make sure the AAB has enough oxygen available, holes are drilled through the ends of the barrel (then covered with muslin) and the barrel is only filled until half full, allowing the maximum surface area to be exposed to air.

Because in the Orleans method the mother of vinegar is left in the barrel for the next batch of wine, the fresh wine must be poured into the barrel very slowly. This is accomplished traditionally using a funnel and glass pipes with a ‘U’ bend at the end. This allows the vinegar maker to pour directly into the bottom of the barrel, thus leaving the floating ‘mother of vinegar’[1] and the residue on the bottom of the barrel undisturbed. It is very important that the mother is not disturbed as if it sinks to the bottom of the vinegar, the ABB within the mother will be deprived of O2 and the mother will rot and ruin all the vinegar.

The joy of brewing vinegar in a small artisan environment is that the product does not have to be the same every time; the differences between batches should be celebrated. From year-to-year, orchard-to-orchard, tree-to-tree, fruits are different as will be the results of processing them in any way. Really no effort should be made to standardize but rather to celebrate the individuality of each crop.

Apple and pear vinegar, however high quality, tend to have little of their original fruit character. However red fruits, such as plums, cherries and blackcurrants seem to be capable of maintaining their character, and, analogous to many red wines, benefit from aging. They maintain their character and develop in time, mellowing out and becoming smoother and less ‘green’. All vinegars will benefit from an aging process in a dark and cool environment.

The strength and fermentation speed of the AAB is reliant on many things, but as a species/genera that can mutate and adapt so quickly (due to short life cycle) they become more efficient after they have been fermenting the same substrate for a longer time. They have become more adapted.

Technological Advances

The Orleans method, was then developed into a faster method, ‘submerged acidification’ which allows the AAB increased contact with oxygen and therefore permiting a faster acidification. The submerged acidification method has then been further developed by Frings Inc into the ‘Frings Acetator’. This is a relatively large piece of machinery which is only worth investing in after production reaches a certain level, it does however allow the production times of vinegar to go down to around 6 hours per batch. The acetator is formed of three tanks, the main central tank is where the second fermentation occurs, when alcohol is converted into acetic acid. The ‘Frings Acetator’ works quickly by pumping 1600 L of air per hour thorough a carbon filter and into a type of blender where it is “atomized’ into the alcohol substrate. The alcohol is acetated at 30 °C and the acetator is equipped to keep this temperature stable. Depending on the strength of the acetic acid bacteria one could expect to have the vinegar ready in a Frings machine anywhere between 20-8 hours and sometimes as low as 6 hours.

When one batch is ready, one third or more is siphoned off and this is replaced with fruit wine. This keeps the AAB culture happy with more food in the form of alcohol and allows this next batch of alcoholic liquor to be acetated. The vinegar is siphoned off when the alcoholmeter reads low enough to make the vinegar legal (ie less than 0.5% alcohol by volume).

At Meyer’s, the multifaceted food business of Claus Meyer, we were fortunate to spend some time with Andreas Harder, a vinegar maker. He was kind enough to explain many of his tricks and give us starter cultures with which to continue our own experiments. One particularly interesting strategy he explained was the problem of changing over from one fruit wine to another when acidifying with only one Frings Acetator. This is approached by always getting darker progressively so the order in which the wines pass into the acetator is apple-pear-plum-blackberry and not the other way around. When changing over the fruit 9/10ths of the 1st vinegar are removed and the volume replaced with the new fruit. Legally the vinegar can still be called by the name of the fruit with the higher concentration, without mentioning the starter culture.

When the annual cycle is finished one must return to the first, apple wine (cider). In order to make this transfer easy a certain quantity of the last batch can be kept. Although the AAB will become dormant, due to a lack of alcohol to metabolise, the unpasteurised vinegar will continue to house this ‘sleeping’ state until the next year or the next apple brewing session.

Andreas also explained to us the measurements he must make before selling his vinegar, in order to ensure it is both legal and appealing. These are:

– Initial Alcohol content by volume: 6-9 % preferred

– Acidity by volume of starting liquid as high acidity of alcoholic culture will lead to a lower acidification.

– Sugar: the residual sugars are very important to predict taste.

– Final measurement taken is of acidity, which must by law be over 5 %. This is tested by titration using NaOH 1 M. If you put 6 ml of vinegar to titrate the number given by the burette will be exactly the concentration of the acidity in the final liquid.

Experimental Vinegars

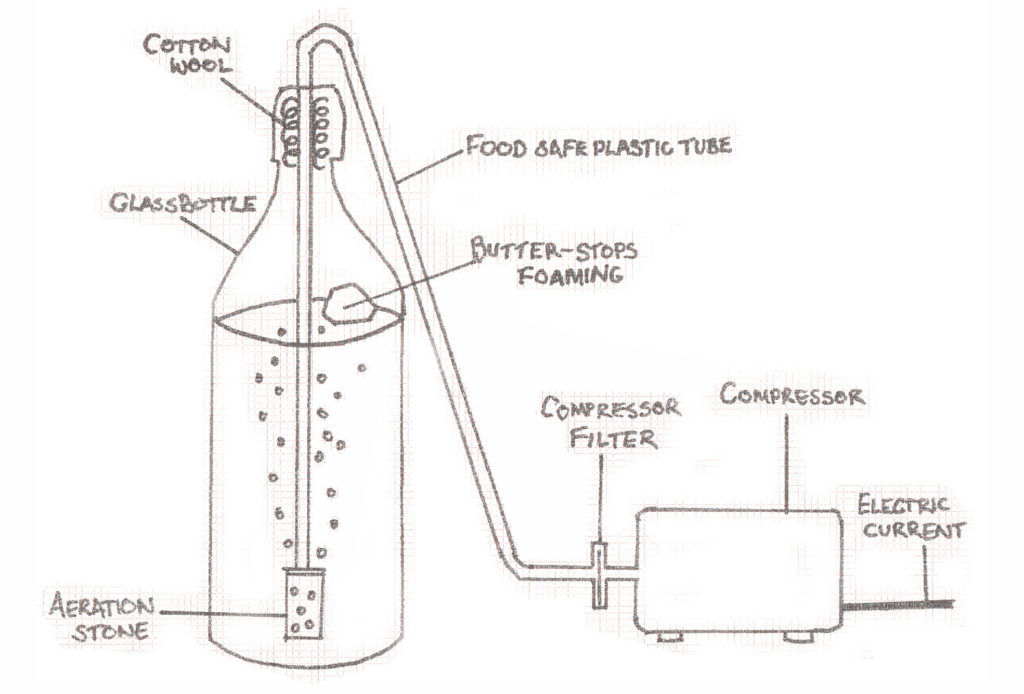

At NFL we experimented with producing various novel vinegars. To experiment with flavours, single stage fermentation was carried out by adding alcohol directly into a juice or solution. This meant that the vinegar process could be accelerated considerably. This process, which gives a second quality product (traditional two stage alcoholic-acetic fermentation should always be carried out in the production of high quality products) proved useful in investigating which flavours should be further investigated. In order to further accelerate the process we designed the following process, using an air compressor (designed for an aquarium) to pump air through a bubbling stone into the alcoholic liquid. Using the apparatus illustrated below and with appropriate inoculation with live unpasterised vinegar, a 5 % (ethanol by volume) ‘wine’ could be fully acidified in 4-5 days. Four successful vinegar recipes are detailed in the following pages.

Mushroom vinegar

- Put frozen whole, washed button mushrooms into oven at 200°C

- Roast until dark through ‘toasting’, removing and keep liquid as it collects

- Fill a pressure cooker with roasted mushrooms, liquid collected, and water

- Pressure cook for 60 mins @ 15psi

- Cool and strain, squeezing the mushrooms well.

- For 95g of mushroom stock add 6g ethanol and 30g unpasteurised apple vinegar.

- Leave in a wide mouthed jar to acidify. Unfortunately it is not possible to use the bubbler system for this recipe as it creates a large amount of foam.

- When repeating the recipe, in step 9. Use 30 Parts of this recipe instead of apple vinegar to slowly fade out the apple.

Elderflower, elderberry, woodruff and liquorice vinegar

- Make a traditional dry, non-sparkling elderflower wine

- When they come into season add ripe elderberries and leave two weeks to macerate

- Strain and squeeze the berries from the liquid

- Add 80 g of powdered liquorice root per 1 liter water and bring to 80 °C for 1 hour. Strain and add this to the elder wine – quantity to taste

- Add a handful of dried Woodruff, and 1/3 by volume of suitable vinegar starter (perhaps apple the first year, and this recipe the second.

- Leave to acidify for 3 months in open topped jar covered with a piece of Muslin to keep flies away.

Celery vinegar

- Juice celery, straining through a fine sieve

- Add 5 parts pure alcohol and 10 parts starter vinegar to 95 parts celery juice

- Put the mix into the bubbler system and wait until alcohol has turned into acetic acid.

[1] Mother of Vinegar – a floating cellulose gel of AAB, which sometimes forms in vinegars. Seen by some vinegar makers as beneficial and some as undesirable.